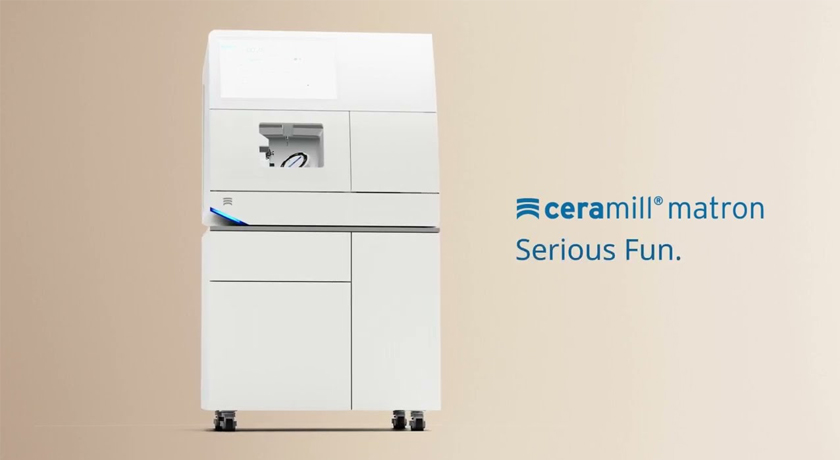

Ceramill Matron

Ceramill Matron

No matter whether you are an expert or a CAD/CAM newcomer: you will benefit from outstanding precision and excellent milling results at high speed across a wide range of materials, particularly in the field of carbide processing. The newly developed, innovative Vmax arm for maximum strength and precision, the retractable Performance Blank Changer, RFID-supported tool and blank management, as well as guided workflows on the 21.5" touch display are just some of the features which make the Ceramill Matron so unique. Integration into the laboratory environment is incredibly easy to implement. The Ceramill Matron is the perfect product for everyone wishing to advance the digitization of their prosthetic workflows and who have the highest demands for quality, cost-effectiveness and enjoy exercising their craftsmanship.

All materials without compromises

The newly developed, innovative Vmax arm ensures maximum power and precision. The unique 45° arrangement of the A/B axes ensures maximum rigidity and highest precision with vibration damping properties in the milling process. The sturdy cast aluminum body, the 6 mm shaft and the high contact surface of the holder support these properties. Due to stable processing with maximum degrees of freedom, this enables virtually unlimited machinability of all common dental materials and indications.

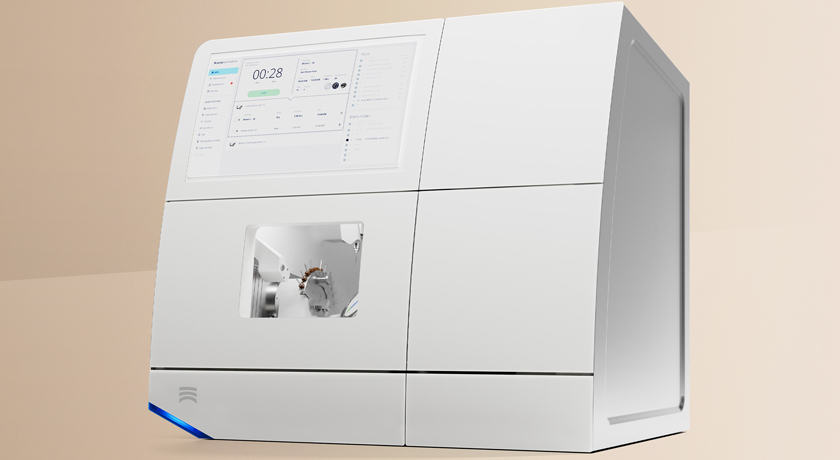

Simply intelligent

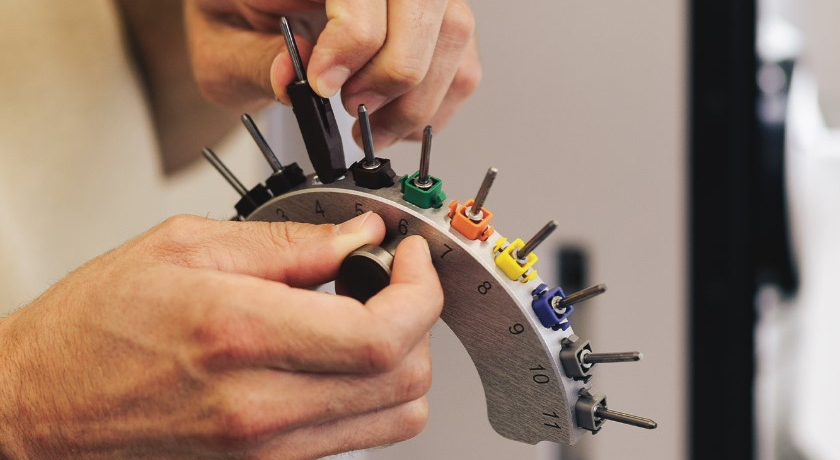

The high-resolution display of the Ceramill Matron guides you safely through all workflows. Check cutter wear, prioritize your workflows. Ceramill Matron offers optimum support. The magnetic, RFID-supported 11-tool carrier makes cutter management simplicity in itself - an unlimited number of cutters can be easily introduced via Plug&Play. With intelligent preloading, many materials and indications can be processed without the need for changing, the magnetic mechanism in combination with RFID technology makes changing tools fast and convenient.

Technical Data

Compatible with plastic, metal, ceramics, hybrids and zirconia

Retractable 8-fold blank changer, RFID supported

Industrial zero point clamping system

HD camera for assistance in support cases

Highly stable machine design with Vmax arm

5+3-axis control for controlling the mechanics

21.5" curved touch display with guided workflows

Min. compressor requirement: 50l/min at 6 Bar

Dimensions (DxWxH): 696 x 940 x 850 mm

Weight: 150 kg

Power consumption: 220 W

High-performance power spindle: 80.000 rpm & 1.37 KW power

SnapMag with 11-fold tool management

Video

Contact

Unit 53/11-21 Underwood Rd Homebush NSW 2140