Amann Girrbach Ceramill Matik

Amann Girrbach Ceramill Matik

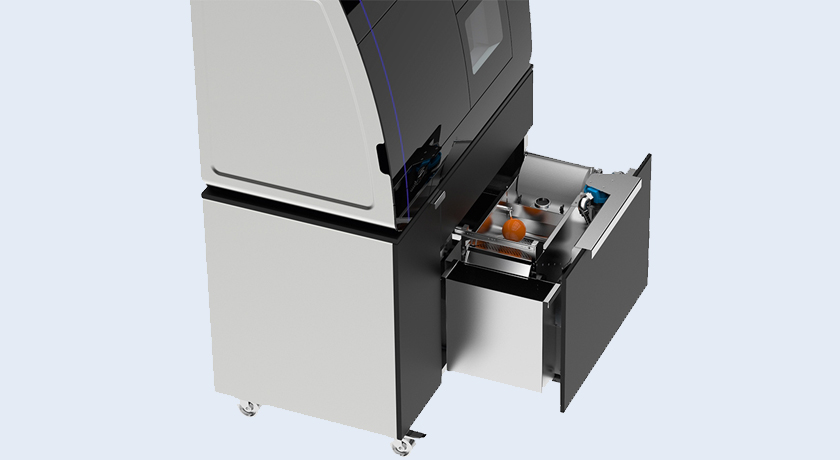

Ceramill Matik opens up a still unique segment within the digital dental CADCAM world. As the first full service unit, it combines three machines in one. Apart from the actual processing station, the system also performs the functions of a fully automated stock management system as well as a machine cleaning device.

The support in loading, cleaning and in material management allows massive time savings in everyday laboratory routines. Furthermore, additional software tools help to make optimum use of the materials and the tools. Due to RFID*, it does not matter whether the resources to be used are placed inside or outside the system.

Yet another highlight is the newly designed 5X machining station. In development, for example, the main focus was on the maximum diversity of indications and materials. Ceramill Matik therefore offers innovative processing methods such as the patented carving mode (60 % time saving), thrilling (production of one-piece abutments) and speed milling of acrylic materials, as well as the maximum material range from hard and brittle block materials to zirconium and PMMA materials and metal materials.

Your benefits

- Maximum time savings in resource management through automatic management of tools and materials

- Highest possible convenience due to autonomous wet and dry change and automatic cleaning

- Full range of applications due to maximum indication and material portfolio

- Future-safe due to constant software development and expandable holder portfolios

Technical Data

- Axes (processing + management): 5 + 4

- Processing mode: autonomous dry/wet

- Spindle torque: 11.2 Ncm

- Spindle speed: 100.000min-1

- Tool management: replaceable 27x tool stock

- Trays with RFID management, management of replacement tools

- Material management: automatic material management with RFID-supported material holders, 36-fold blank tank

- Dimensions system (DxWxH): 780 x 1265 x 2000mm

- Weight of system (empty/max): 520/625kg

- Compressed air peak: 200l/min at 6bar in the cleaning mode

Indications

- Crown/bridge full contour/contour reduced

- Inlay/Onlay

- Veneer

- Overpress full contour

- Telescopes

- Sliding element

- One-/multi-part block abutments

- Titanium abutment individual

- Bridge on conical titanium bases

- Multi-pontic screw-retained construction on Ti bases

- Bar on titanium bases

- Bite splints

- Eggshell temporaries

- Partial/full dentures

- Digital model creation

Video

Contact

Unit 53/11-21 Underwood Rd Homebush NSW 2140