VHF R5

by Henry Schein

VHF R5

With the R5 – a new high-end machine for the dental laboratory – vhf has developed a highly automated milling and grinding machine that brings revolutionary approaches to the lab along with a ten-fold blank changer for wet and dry machining. In a minimal footprint, it combines utmost precision with maximum stability and is capable of handling any material.

vhf R5 – high-end dental restorations non-stop

The R5 is a highly automated milling and grinding machine with ten-fold blank changer. See for yourself how easily you can revolutionize your lab and in-office lab with this ingenious wet and dry mill, combined with maximum ease of use.

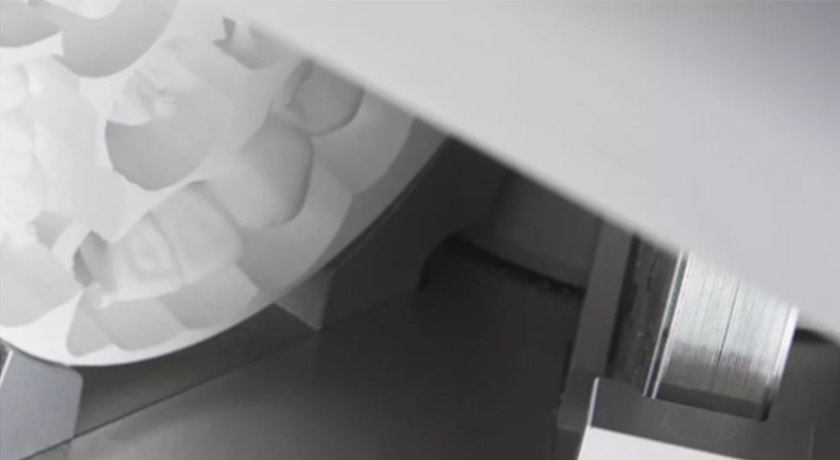

Simple and effective: DIRECTDISC Technology

DIRECTDISC Technology ensures that blanks can be clamped quickly and without tools – allowing them to be processed directly.

DIRECTCLEAN Technology for a quick switch between wet and dry

The R5 effortlessly switches between wet and dry machining. In addition to ionizers and active workspace ventilation, the machine also offers an intelligent drying function.

Just clear water required

For wet machining, the R5 grinds and mills with clear water which you just have to fill into the integrated water tank. For all materials, except titanium, without any additives – better for your materials and without annoying disposal.

Maximum freedom regarding materials and sizes

Another highlight is the ability to process milling blanks up to 40 mm thick. Perhaps even more important is the generous tilt angle of ± 35 degrees for the spindle axis. The R5 thereby guarantees a maximum of indication variety and provides high freedom of design.

Highest precision

- Restorations in Ultra HD

- High-precision spindle with 800 watts of power and 80,000 rpm

- 3 μm repetition accuracy

Tremendous stability

- Mills and grinds the toughest materials on the market including all titanium and CoCr materials

- Proven industrial quality

- Solid cast-body for minimum vibrations

Absolute independence

- Sheer unlimited material variety in 98 mm disc format, around 40 block materials, and

800+ titanium and CoCr prefab abutment blanks - Covers the broadest range of indications, due to ± 35° rotation angle in the 5th axis, and up to 40 mm disc height

Outstanding reliability

- 100 % engineered and manufactured in Germany

- Comprehensive sensor technology to monitor all vital system functions

- 24-month warranty

Highly economical

- One of the fastest machines on the market

- Revolutionary material loading with DIRECTDISC Technology (patent pending)

- Automatic changer holds up to 10 discs, 60 blocks, or 60 prefab abutments

- Webcam in working chamber for remote monitoring and service

- DIRECTCLEAN Technology enables wet and dry on the fly: ionizer, self-cleaning and built-in dryer (patent pending)

- Drilling of screw access channels – saves costs for “meso” blocks

- Very easy operation via DENTALCAM software with DIRECTMILL Technology – included in scope of delivery and without license fees

Video

Contact

Building 3, Level 6, 189 O'Riordan Street, Mascot, NSW 2020