The influence of the zirconia sintering temperature on its color shade

02/06/2019

The influence of the zirconia sintering temperature on its color shade

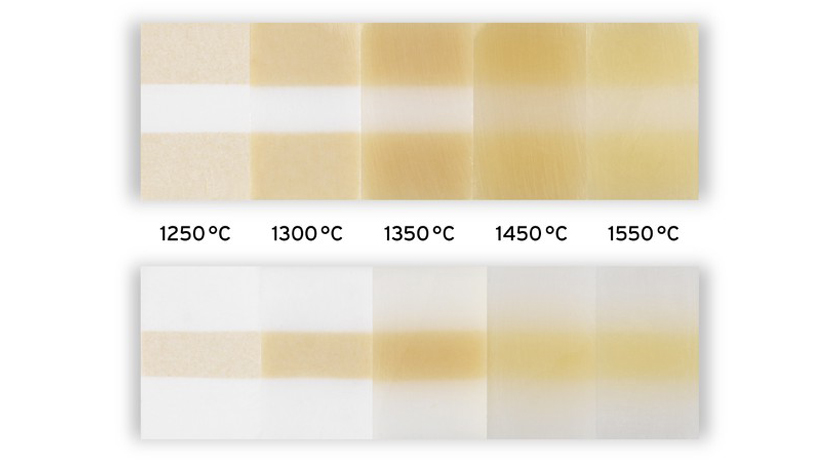

The significance of maintaining the sintering temperature for zirconia is meanwhile sufficiently well established with regard to the influence on strength and translucency. However, when using pre-stained blanks, there is an additional influencing factor. The color shade of zirconia also changes depending on the sintering temperature, as can be seen impressively from the specimens illustrated in Figure 1.

If the sintering temperatures are too low, the zirconium oxide is less chromatic and the blending of the shade layers is insufficient. With increasing sintering temperatures, an increasing shade intensity of the yellow areas is clearly recognizable up to a sintering temperature of 1450 °C. At this ideal temperature, the expected color shade is created as is the desired blending between the shade layers. With a further increase in sintering temperature, for example to 1550 °C, the shade intensity decreases again. The specimen appears less chromatic.

It is therefore not advisable to differ from the sintering temperature specified by the manu-facturer, as this will result in a negative change of the shade result.

Contact

Unit 53/11-21 Underwood Rd Homebush NSW 2140